Modular Conveyor Solutions for North-East Link Project

In the realm of infrastructure development, Fenner Conveyors has emerged as a leader for customised and modular conveyor solutions, with recent success delivered for a key infrastructure project in Victoria.

The North-East Link Project plans to fix missing links in Melbourne’s freeway network, take 15,000 trucks off local roads every day, and reduce travel times by up to 35 minutes. To create these vital transportation lines, 6.5km of tunnels are being constructed spanning regions beyond Melbourne CBD.

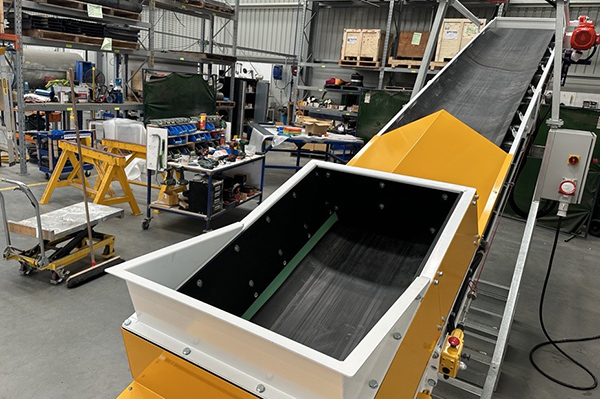

The Fenner Conveyors team in Dandenong, Victoria have supported this project with the delivery of a custom-designed concrete conveyor system.

Modulaveyor systems are ideal for construction projects, through a light-weight design for easy transport and installation. Being easy to assemble and disassemble, modulaveyors are the perfect option for conveyor systems that need to be relocated regularly across the duration of a project – such as the North East Link Project.

The purpose-built modulaveyor system, engineered and fabricated by our team in Victoria, will load concrete into moulds with segments making up the new tunnel.

North East Link Precast Superintendent, Peter Nugent, said the modulaveyor system is helping to streamline the construction process, facilitating the swift assembly of tunnel infrastructure with unparalleled accuracy.

“We are highly impressed with the conveyor engineering expertise of the Fenner Conveyors team in Victoria and the delivery of this custom solution in a short time-frame.”

Over the course of the 15-month project, over 4,000 concrete segments will be made using the specialised conveyor system, equating to 24,000 cubic metres of 50mpa concrete weighing a total 57,600 tonnes.

Dandenong Branch Manager, Grant Potter, said that at the heart of Fenner Conveyors' modulaveyor systems lies its adaptability and engineering precision.

“Unlike traditional conveyor solutions, the modulaveyor system offers a customisable approach tailored to the unique demands of each project. The versatility of our modulaveyors ensure seamless integration into diverse construction workflows, maximising efficiency and minimising project disruptions,” explained Potter.

Even with a light-weight design, modulaveyors are engineered to withstand the rigors of construction environments. By harnessing Fenner Conveyors' modulaveyor systems, construction projects can achieve unprecedented levels of productivity and precision.

Beyond the North East Link project, Fenner Conveyors' modulaveyor systems continue to revolutionise bulk materials handling projects. From underground tunnels to surface quarries and warehouse logistics, this innovative conveyor solution offers performance and versatility, driving progress and innovation in diverse industries across Australia.